From the lacquer forests

Only less than 6% of the used lacquer in Japan is domestically produced. The production area of lacquerware used to be with the producing area of lacquer. Although there are 17 prefectures in Japan that craft traditional lacquerware, Iwate is one of only 11 prefectures that produce Urushi. Iwate is the top production area of lacquer by prefecture, and in 2024 production of Iwate was 1,421 kg, Ibaraki 210 kg and Tochigi 75 kg. Around 80% of domestically produced lacquer is in Iwate, and all the amount is produced in Ninohe, which is Joboji urushi.

Joboji town in Ninohe City has the most lacquer craftsmen in Japan. The lacquer industry had been prosperous here, and there are place names such as Urushizawa, Urushibata, and Urushihara which contains the words “lacquer.” Both lacquer production and lacquer craftsmen have decreased since the 1940s in Joboji as well as other areas. They started to plant lacquer trees in Joboji in order to stop the decline. As a result, Joboji is now the richest area of timber resources. Memorial tree planting is carried out on November 13, the day of lacquer.

Production area of domestic lacquer, leading producing area of lacquerware

Charts

1. In Japan, Iwate Prefecture, Joboji urushi production volume source the Forestry Agency special nutrient forest basic materials, Ninohe City

2. Traditional crafts of lacquerware in each area

Production areas of Lacquerware (Traditional crafts designated by Industrial Ministry)

| Aomori Prefecture | Tsugaru-nuri (coating) (1975) |

|---|---|

| Akita Prefecture | Kawatsura Lacquerware (1976) |

| Iwate Prefecture | Hidehira-nuri (1985), Joboji-nuri (1985) |

| Miyagi Prefecture | Naruko Lacquerware (1911) |

| Niigata Prefecture | Murakami lacquer/wood carving (1976), Niigata Lacquerware (2003) |

| Fukushima Prefecture | Aizu-nuri (1975) |

| Kanagawa Prefecture | Kamakura carving (1979), Odawara lacquer (1984) |

| Nagano Prefecture | Kiso lacquer (1975) |

| Gifu Prefecture | Hida shunkei (1975) |

| Ishikawa Prefecture | Wajima-nuri (1975), Yamanaka Lacquerware (1975), Kanazawa Lacquerware |

| Toyama Prefecture | Takaoka Lacquerware (1975) |

| Fukui Prefecture | Echizen Lacquerware (1975), Wakasa-nuri (1978) |

| Kyoto Prefecture | Kyo Lacquerware (1976) |

| Wakayama Prefecture | Kishu Lacquerware (1978) |

| Yamaguchi Prefecture | Ouchi-nuri (1989) |

| Kagawa Prefecture | Kagawa Lacquerware (1976) |

| Okinawa Prefecture | Ryukyu Lacquerware (1986) |

The lacquer forest is

“the forest of cultural treasure.”

Treasures of our country such as national treasures and important cultural asset need repairing to pass down into the future. As most cultural assets are made of natural materials, lacquer used for repairing lacquerware, sedge for thatched roofs should be maintained and at the same time technicians who can treat these materials should be trained. Consequently, the Agency for Cultural Affairs set up “the forest for cultural assets” and has conducted skill training and “Promotion project of hometown cultural assets system.

The lacquer forest of 4ha in Myojin-zawa district which Ninohe City owns was certified as the first “hometown cultural asset” in 2007. In the whole town, the area of lacquer forests is 144ha, and the number of lacquer trees is 140,000. Subsidy system of saplings has promoted raising lacquer planting.

Japan Geographical Indication Registered Product Joboji Urushi

Joboji Urushi is a registered product of the Geographical Indication (GI) system, which guarantees the quality characteristics and production area of specific agricultural and marine products.

- ■Registration Number

- 73

- ■Registration Date

- Dec 27, 2018

- ■Name

- Joboji Urushi

- ■Producing Organization

- Iwate Joboji Urushi Producer’s Association

- ■Characteristics

- Lacquer with a very high post-curing strength, as well as stable quality. Excellent durability, and a rich variation in transparency, curing time, viscosity, etc.

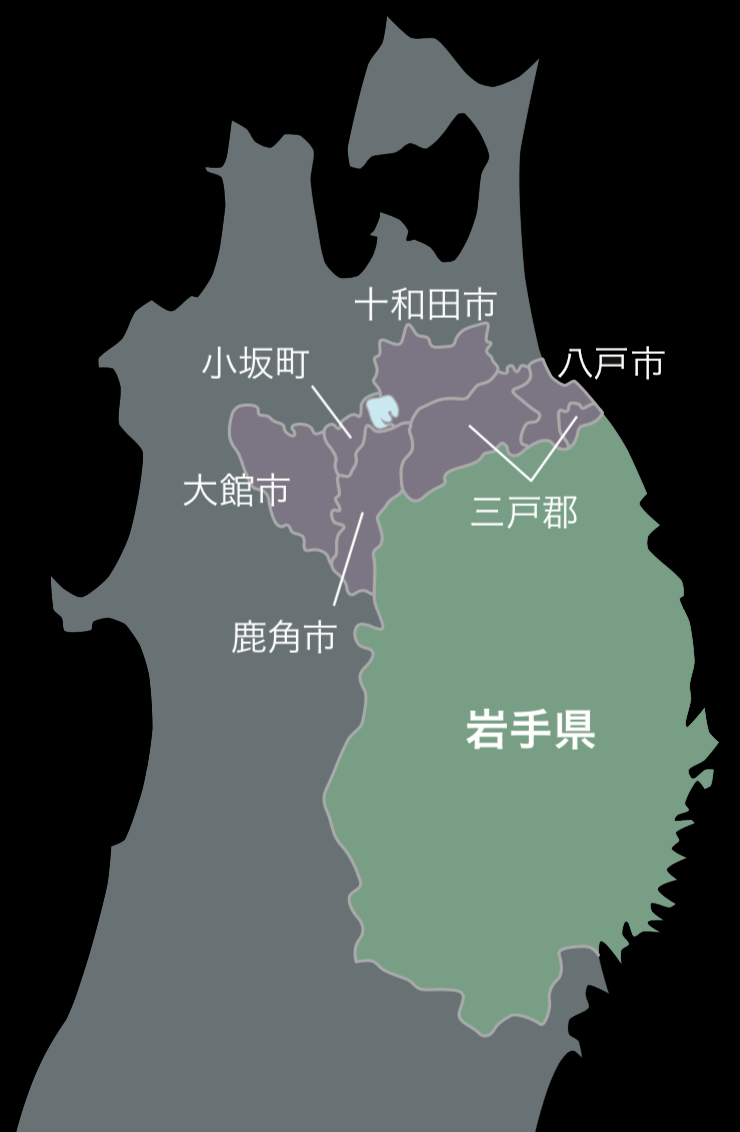

- ■Production Area Range

- The whole of the Iwate; Sannohe District, Hachinohe, and Towada in Aomori; and Kosaka in the Kazuno District, Kazuno, and Odate in Akita

The Two Guarantee Marks of Joboji Urushi

Geographical Indication (GI) Protection System

The GI system is a national registry that maintains a standard of quality and protects the intellectual property of the names of agricultural, forestry, fishery, and food products that have been cultivated regionally over a period of many years through means of special production methods and earning high ratings.

Joboji Urushi Certification

Japan’s only lacquer certification system. Lacquer that has been certified by the Joboji Urushi Certification Committee, a third party institution established in Ninohe, bears this brand mark.

The Lacquer Culture of the Ninohe Area

Records show that trees were planted with encouragement from the Edo period Morioka Clan, making for a region that has regarded lacquer trees as valuable assets since long ago. As the trees will not mature into ones that will provide sap without proper management and removal of weeds and other growth, local people have strived to create an environment that provides optimal growth for lacquer trees.

Since shifting to a method that allows for lacquer collection and tree harvesting in one year’s time during the Meiji period,Since shifting to a method that allows for lacquer collection and tree harvesting in one year’s time during the Meiji period, work has also been carried out in efforts to regenerate lacquer forests by managing sprouting buds after harvesting, and such methods have been inherited into present day practice, with a focus on coexisting with nature and protecting and nurturing the forests that provide Joboji Urushi.

Inherited Lacquer-tapping Techniques

During the Meiji era, lacquer craftsmen from the current day Imadate area in Fukui, known as Echizen Shu, came to work in the Ninohe area for rich lacquer trees, and brought with them a method for harvesting lacquer from one piece of tree in just a year’s time, as well as the tools required for doing so. These techniques to determine the state each tree is in, handle tools, and tap lacquer, have been inherited by present day craftsmen.

Craftsmen’s Technique and Collection Time Produce Characteristic Lacquer

Lacquer properties depend on the collection time and technical personality of the individual doing the collection, making for a diverse variety in the nature of each lacquer.

Hatsu Urushi (First Collection): Mid June – mid July… has the advantage of quick drying (hardening).

Sakari Urushi (Peak Collection): Mid July – mid September… used in the finishing stages of applying lacquer, due to its gloss and transparency during the curing process bringing about a best product.

Sue Urushi (Late Collection): Mid September – October… has the advantage of providing a thick coating during the application process.

Urame Urushi (Last Collection): October – November… with a strong viscosity, mainly used in base coatings.

Guardian of Japanese lacquer

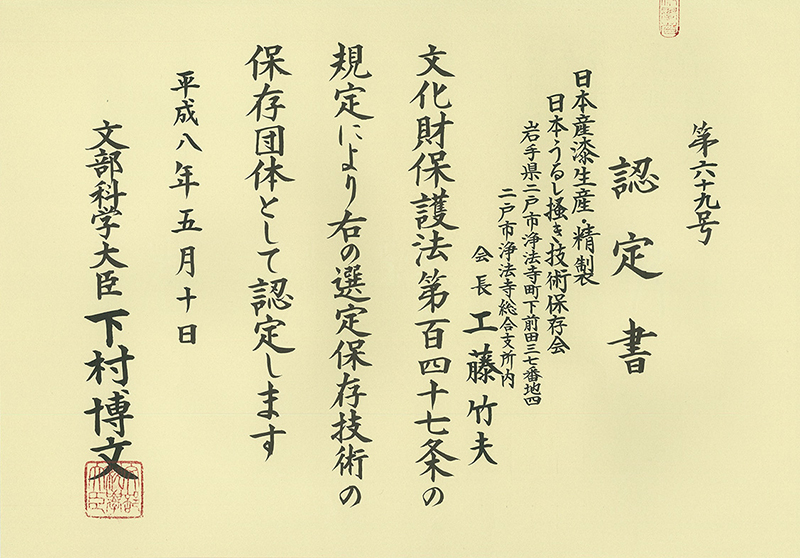

Japanese urushi tapping Preservation Society

Japanese urushi tapping Preservation Society was established in January 1996 for the purpose of the “succession of urushi tapping technique” and “securing lacquer production.” It was certified as preservation society of selected preservation technique, “Japanese lacquer production and purification,” by Cultural Affairs in May that year since the technique was traditional and necessary for maintaining cultural assets, also preserving measures should be taken. It promotes campaigns involving the production of lacquer taken in Japan, such as accepting 42 long-term trainees until 2016, publishing record video and booklets and the like.

Tools of urushi tapping (tools produced by Kudo Takeo)

- 1. Kibera (wood pallet): a tool for scraping lacquer on Gonguri and Tarugake

- 2. Tarugake (for 3kan,11.25kg): a tool hanged on the lacquer barrel for scraping lacquer on Gonguri when lacquer is moved into the barrel,

- 3. Tarugake (for 5 kan, 18.75kg): a tool hung on the lacquer barrel for scraping lacquer on Gonguri when lacquer is moved into the barrel

- 4. Gonguri: a tool for scraping lacquer from the bottom of Takappo (a wooden vessel) when lacquer is moved into lacquer barrel from Takappo

- 5. Eguri: a tool for Uramekaki, tapping the spots undone, instead of the lacquer plane

- 6-8. Lacquer planes: tools with blades for scratching a tree and Mesashi for cutting a notch

- 9-11. Pallet: a tool for tapping sap. The smaller ones are used for tapping branches.

- 12. Hatchet for cutting branches: used for cutting branches to tap

- 13. Peeling sickle: a tool for smoothing the surface of wood by peeling its skin

(Main activities)

■ 1. Training skill keepers

People desire to learn urushi tapping skills are admitted.

Long term training (conducted for 5 months, from June to October): 2-3 persons a year

Short term training experience (three days): the implementation schedule is to be set in each season

■ 2. Training skills and technique

Securing tools, analysis of produced lacquer, checks and inspection visits in lacquer forests and producing areas in Japan and mutual interaction with persons concerned are conducted, and its primary purpose is to support skill holders.

■ 3. Making records and publication

General investigation for grasping skills involved in “lacquer,” oral survey on the lacquer craftsman’s life and skills, lacquerware production for understanding the characteristics of domestic lacquer and projects to record the process of producing urushi tapping tools and making their models.

Publications so far

♦ 1999 『Lacquer-craftsman’s living of urushi tapping』

♦ 2005 『A year of a lacquer craftsmanーOmori Shunzo’s skillsー』

♦ 2014 『Planting trees and tapping lacquerーSuzuki Kenji’s skills-』

■ Others

Information and materials are provided to research facilities such as museums and the media and the like when requested, and activities to promote understanding and awareness of the Preservation Society and “Japanese domestic lacquer.”

Secretariat Preservation Society of Japan urushi tapping skills secretariat (Ninohe City Lacquer industry division)

TEL : 0195-38-4472 FAX : 0195-38-2218